How To Repair Sidewalk Concrete

How to Fix Sidewalks That Are Chipped and Pitted

Updated: Jun. 24, 2022

Roll downwards your sleeves and put on a dust mask. Making a durable patch is a dusty, grimy matter.

Extend the life of erstwhile concrete by fixing cleaved, aging areas before the problem gets worse. A properly done repair volition last decades. We'll show you how to create a durable physical patch to gear up two of the nearly common problems: spalling and broken corners.

You might too similar: TBD

- Fourth dimension

- Complexity

- Cost

- A full mean solar day

- Intermediate

- Less than $twenty

Physical Patch: Size up the job earlier you brainstorm

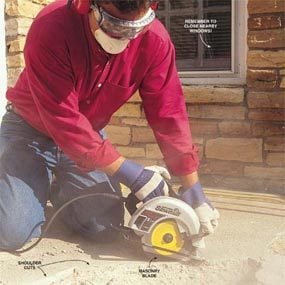

Concrete is difficult stuff, only don't allow that intimidate you. With the proper tools and techniques we show in our photograph series, even a novice can make a durable patch, offset attempt. Sawing concrete with a special masonry blade (opening photo) may be new to you lot, simply if you lot've handled a circular saw, y'all'll apace get the hang of it. It'due south less hazardous than sawing wood. However, the bract kicks up an incredibly thick cloud of abrasive dust, so be sure to wear goggles to protect your eyes, ear protection, gloves and a dust mask, as well as onetime dress.

Size up the job commencement. Before beginning any repair, assess the general condition of the concrete slab. (Run across "Patch or Supervene upon? " below) Sometimes the best strategy is to break out an entire section and repour it with new physical rather than patch it. Patching works best for local impairment in otherwise sound concrete.

We won't bargain with the other common problem, cracks. You can repair them exactly every bit nosotros show here, simply they'll most likely return unless you can stabilize the concrete slab to prevent the movement that acquired the cracks in the commencement identify.

If this is your first concrete repair project, permit well-nigh a half day to pick up materials and complete two to three patches. It took usa about four hours from start to cease to complete the two repairs we show here.

Complete the task during comfy working conditions, ideally in dry weather condition with a temperature betwixt fifty and lxxx degrees F. Both you and fresh physical happen to agree on this one. Fresh concrete is easiest to handle and hardens best (a process technically chosen "setting" and "curing") in this temperature range. Colder weather lengthens the setting time; freezing temperatures tin can ruin the physical. Hotter weather causes faster setting and drying; the slab may harden earlier you lot can polish it. Or the surface can dry also fast and not harden properly, somewhen causing it to spall. In hot weather, work in the cooler mornings or in the shade.

Patch or Replace?

Should yous patch your erstwhile concrete or completely tear information technology out and repour information technology? While there's no hard and fast dominion, here are some tips to guide your decision:

- Assess the severity of the damage. If your driveway is total of spalled areas and cleaved edges, the surface is probably severely weakened. Information technology'll continue to deteriorate, and chances are the patches won't terminal.

- Call in a physical contractor (Search "Concrete Contractors" on your browser) to assistance you lot appraise the state of affairs and ask for a price on complete replacement. But continue in heed that contractors are in the business organisation of selling concrete. With their labor costs, it's ordinarily cheaper for them to replace than repair. Nosotros had problem finding a contractor who would even exercise patching.

- Is appearance of import? A patch will exist lighter-colored than the old concrete. Fifty-fifty subsequently weathering for a few years, the new patch will probably still stand out. One way to hibernate the patch is to stain the unabridged surface to blend the old with the new. Simply you'll have to renew the stain periodically.

- How much are you willing to spend? Cloth costs for a repair are low. Pros would want to completely supersede the slab to insure a high quality result. The cost would be substantial.

Repair spalled areas: Cutting out the impairment

"Spalling" is the mason'southward term for concrete that's pitted or chipped, equally in Photo 1. The central to a lasting repair is to make a saw cut effectually the perimeter of the damaged expanse, cutting dorsum to solid concrete. The cut should be at least 3/8 in. deep: Most repairs that fail do so considering the patch is as well thin at the edges and breaks off. Set a masonry blade (run across above) at a 5-degree angle so the cutout is slightly wider at the bottom than at the top. This helps "lock in" the patch (Photo i). Slowly guide the saw through the concrete. The masonry bract grinds a groove, so don't put a lot of pressure on the saw; permit the bract practise the work. Cutting most ane/4 in. on each pass. A diamond grit blade can cut the concrete about five times faster than a masonry blade, and it won't wear out every bit fast. Merely it also costs more. The extra cost is worth it if yous accept more nigh 10 ft. of concrete to cut. Or save money—and time—past renting a diamond blade (about a day, plus wear fee), or a physical saw with diamond blade.

Tip: You'll enhance an impressive dust cloud when sawing, so shut up nearby windows and doors. Otherwise, y'all'll be housecleaning, too!

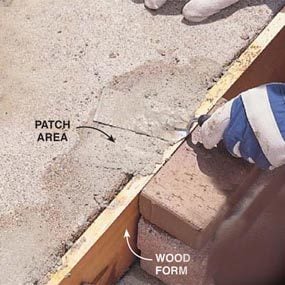

Once y'all've cut and thoroughly cleaned loose physical from the repair area (Photos 2 and 3), moisten the area with a moisture sponge earlier packing in the concrete mix. Don't leave standing h2o in the patch area; use just enough to dampen the old physical and help it bond to the new.

Repair spalled areas: Pack in the repair mix

For your patching mix, use either a prepackaged sand mix or physical mix, depending on the depth of the patch. (See "Employ the Correct Patching Mix, " beneath.) Each 60-lb. bag makes about 1/2 cu. ft. of concrete, enough for a 2-in. thick patch about 1 ft. wide by 3 ft. long. Estimate the book of patching textile by multiplying estimate length, width and thickness (in feet) to arrive at cubic anxiety, and purchase a bit more than you think y'all'll need. Better to accept too much than to fall a few scoops brusk!

Mix it with water and acrylic fortifier, post-obit the mixing directions on the package. The fortifier strengthens the new physical and helps it bond better to the erstwhile concrete. The mix should exist but wet plenty to hold together when information technology's troweled into the repair. Don't add as well much water. It'll issue in weaker concrete.

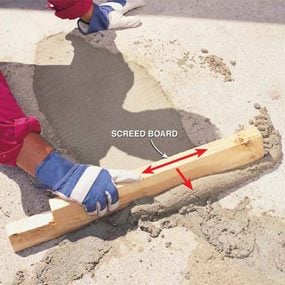

Nosotros used a normal sand mix, which sets hard enough to walk on in about a day or two. Information technology continues to cure and harden for weeks. If yous take to use the surface area right abroad, you can buy a special fast-setting concrete, which hardens in about an hour. It costs about twice as much and y'all won't have as long to spread and polish it, so stick to the regular mix when possible. Most building supply dealers that carry regular concrete also carry the fast-setting type. After mixing the physical, pack information technology firmly into the repair expanse using a woods float (Photograph 4), the tighter the better. Mound the mix so it's slightly higher than the old physical. So immediately level it even with the old concrete using a straight board (Photo 5).

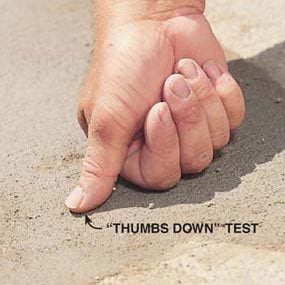

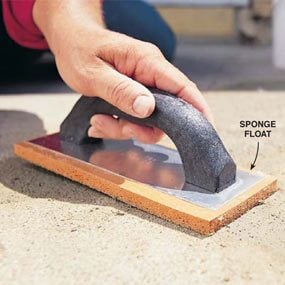

Begin finish trowel work when the surface moisture starts to evaporate and the patch begins to harden. It may only be 10 minutes on a warm day or possibly an hour on a cool 24-hour interval. One sign of evaporation is the loss of some of the surface gloss. When the patch appears to be getting potent, test it with your pollex (Photo 6). Once the surface is about as potent as the peel of a grapefruit, begin the finish work. We used a sponge bladder (Photograph seven) to match the slightly rough texture of the old concrete. A sponge float has a rough prophylactic surface. If you want a smoothen surface, use a steel trowel; for a lightly grooved appearance, elevate a strong-bristle broom across the surface.

Later on using a bladder on the surface, cover the patch with plastic for two days. The plastic helps the concrete retain the moisture, which the concrete needs to cure and strengthen (Photo eight).

Circumspection!

Wet physical is highly alkaline metal and can crusade severe burns to bare skin. Immediately launder off any that gets on your skin with cool water.

Use the Correct Patching Mix

Concrete mix consists of sand, gravel and Portland cement. The gravel reduces shrinkage, so it won't crack every bit readily when laid in thick. However it may not bond well in thin layers. Sand mix (sometimes chosen topping mix) consists of sand and Portland cement. Information technology's easier to trowel in thinner layers (to about 1/4 in. minimum) for thinner patches or patches with thinner edges. However, if you utilize information technology thicker than two in., its natural shrinkage might cause it to crack or suspension the bond with the old concrete. In a nutshell: Utilize a sand mix for repairs less than ii in. deep. Use a physical mix for repairs deeper than two in. Supplant 50 to lxxx percent of the water with the acrylic fortifier in either mix to improve the patch's bonding forcefulness.

Concrete Patch: Repair broken corners

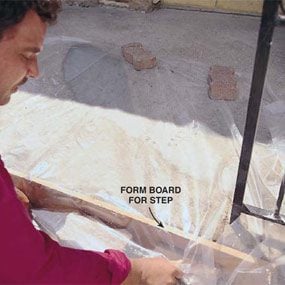

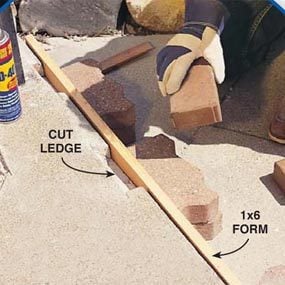

Use the same basic patching technique for a broken corner as for spalled areas, but add three cardinal steps.

- Create a ledge for the patch to make a stronger bond with the old concrete (Photos 9 and ten). Don't be afraid to make the cutout well beyond the edges of the original damaged area. Smaller patches just won't hold as well as larger ones.

- Prop a wood form tightly against the vertical portion of the step to concur the concrete patch in identify (Photograph x). Block the class against the step with bricks or other heavy objects. Tip: Coat the wood form with motor oil or WD-40 to continue the concrete from sticking to the wood.

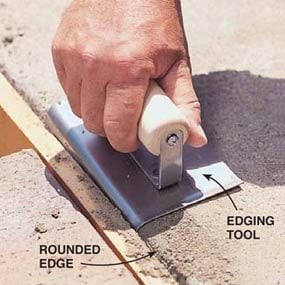

- When the concrete begins to set, employ the edging tool to create a slightly rounded edge to match the step (Photograph eleven). Then remove the form board (carefully, considering the physical is notwithstanding soft) and finish all exposed surfaces with a bladder or trowel to lucifer the texture of the old concrete. Cover the patch with plastic and permit it cure for at to the lowest degree ii days before walking on it.

Required Tools for this physical patch project

Have the necessary tools for this DIY project lined upwardly before you first—you'll relieve time and frustration.

You lot will also need a 2lb. maul, forest bladder, sponge float, edging tool, broom and a masonry blade.

Required Materials for this physical patch project

Avoid final-minute shopping trips by having all your materials prepare ahead of time. Here'southward a listing.

Originally Published: June 24, 2022

Source: https://www.familyhandyman.com/project/how-to-fix-sidewalks-that-are-chipped-and-pitted/

Posted by: gemmillyouser.blogspot.com

0 Response to "How To Repair Sidewalk Concrete"

Post a Comment